Industry Solutions

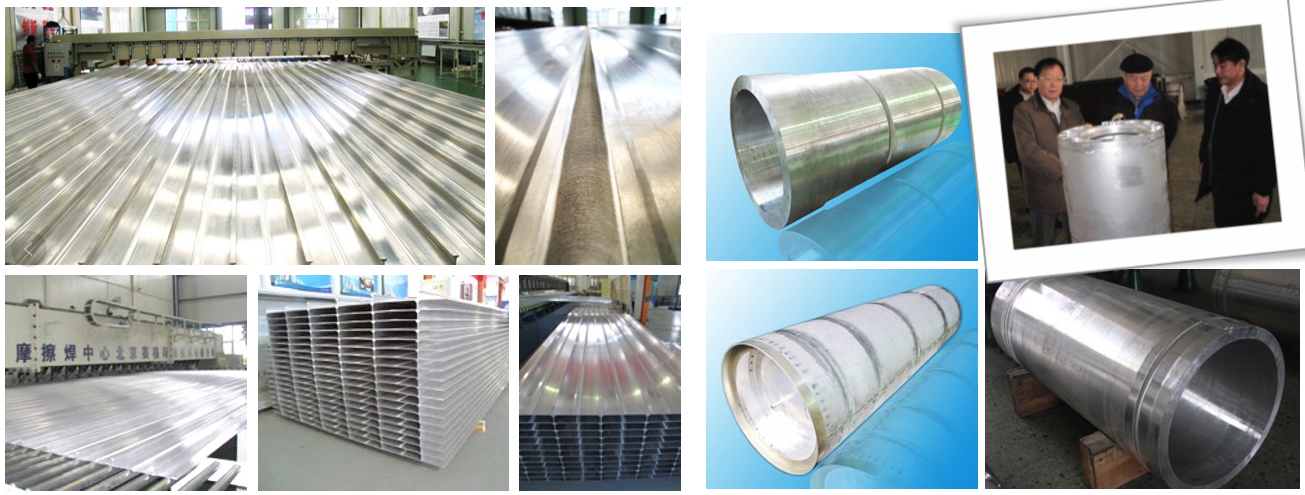

In 2019, saifoster and Ningbo Jingcheng Machinery Manufacturing Co., Ltd. of aviation industry reached a strategic partnership. The company's business moved to the field of friction stir welding, and actively cooperated with saifoster to develop friction stir welding equipment and special friction stir welding fixture in the field of industrial metallurgy. Ningbo Jingcheng Machinery Manufacturing Co., Ltd. has rich experience in the welding of anode and cathode plates. At present, it has been put into production in Yunnan as the "production base of plate components".

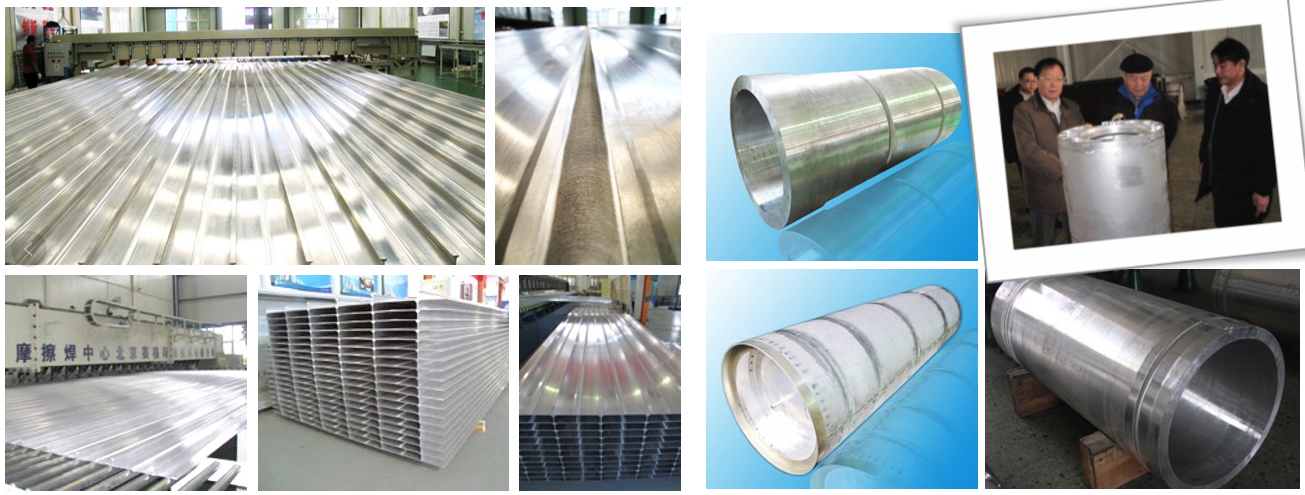

Equipment of seiforster metallurgical industry

Saifoster company of AVIC has realized the high efficiency and low cost batch production of plate components by adopting the self-developed high-automatic friction stir welding equipment, and has put into production the "production base of plate components" in Yunnan, which has greatly met the market demand and set off the welding revolution of cathode and anode plate components for metallurgy.

Since its establishment, saiforster company of aviation industry has successfully developed a number of special friction stir welding equipment for electric power, electronics and other fields, which are used for the mass production of structural products such as radiators and heat sinks.

In 2011, saifoster company of aviation industry successfully developed the plane two-dimensional numerical control friction stir welding equipment and supporting process for water-cooled plate welding, and realized the friction stir welding of 17mm thick copper alloy water-cooled plate products, making China the third country to successfully develop such a large-scale copper alloy friction stir welding water-cooled plate products after the United Kingdom and Japan.